Cardinal Air Design was approached by a Northwestern PA manufacturer to address issues with their aluminum shot blast process. They need to use a dust collector, but wanted to locate it inside. Problem Aluminum shot blast produces combustible dust. There are a lot of regulations regarding dry dust collection and combustible metal dust. It is extremely … Continued

Blog

Cardinal Air Design was approached by a Northeast Ohio plastic recycler to address issues with their pulverizing process. Their existing system uses positive pressure bags located inside the facility to filter air from their pulverizers cyclone exhaust. This created a number of issues inside the facility. Problems Noise: Due to the fans … Continued

We recently worked with a company whose process involved metal printing. If you’re familiar with metal printing, you know that it gives off an offensive odor, especially in a smaller room. We were dealing with two of the same printers in an enclosed area with air conditioning being the only form of air circulation. We … Continued

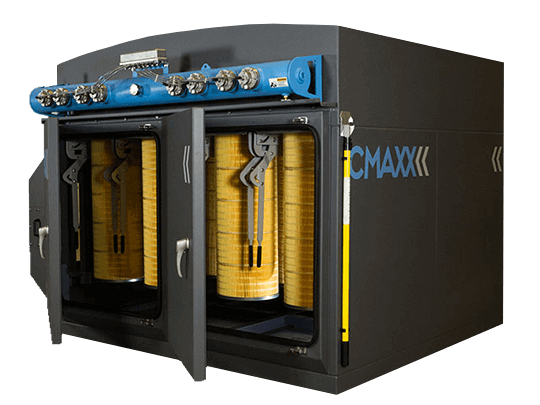

From an Imperial Systems blog post in 2019: PROBLEM: A company in Ohio produces parts for the aerospace industry using a salt bath. The modern aerospace industry relies on salt baths to treat metals for corrosion resistance. However, the high heat and particulate from this process caused serious problems for the company’s dust collector. The … Continued

We’re providing this handy guide so that if you want to damage your dust collector filters, you’ll have lots of ways to do it. Assuming you want your filters to last as long as possible, you may want to avoid doing any of these things. Cartridge dust collector filters are made of a cellulose and … Continued

FPA combustible dust standards cover the general requirements for wood, food processing, and combustible metal dusts, but some industries have special needs and risks. Wood processing and woodworking (NFPA 664) make up a large percentage of combustible dust accidents. The agriculture and food processing standard (NFPA 61) deals with combustible dust incidents in this industry, which also has … Continued

You may need replacement dust filters for your Imperial Systems dust collector or even a competitor’s. Now we’re making it easier than ever to get a quote. Do you have a dust collector from Donaldson Torit, Camfil Farr, Robovent, Lincoln Electric, or others? We’ve certainly made it easier to get the best replacement cartridge dust … Continued

If you need to prevent a dust collector explosion in your facility, following NFPA standards will guide you in the right direction. NFPA 69 Standard on Explosion Prevention Systems covers many different methods for preventing explosions. This standard covers many types of explosive materials, but we’ll focus on the parts that apply to dust explosion … Continued

Grain Dust Risk

Blog

A small amount of excess dust probably doesn’t sound like too much of a problem. After all, what process occurs without a little dust? What most people don’t consider is what can happen if this dust is exposed to an ignition source. While some ignition sources present in grain processes are obvious, others … Continued

According to NFPA standards, explosion venting is a key part of dust collector safety. NFPA 68, the Standard on Explosion Protection by Deflagration Venting, lays out these guidelines. Dust collector explosion venting, also called deflagration venting, allows pressure to safely escape during a fire. Without explosion relief venting, a dust collector fire can cause … Continued